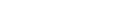

Hollow fibre ultrafiltration membrane cassettes for MBR applications designed to prevent fouling and clogging and make its operation easy and simple in industrial waste water treatment plants

Our membranes area made of PVDF with a pore size of 0,02 µm and a pore distribution in the capillary that allows for an excellent chemical and mechanical resistance. The Smart design of the air diffusers along with the horizontal lay out and a particular distribution of the membrane bundles avoids dead areas in the membrane tank and an effective scouring of all the capillaries keeping the membranes clean and the flow stable.

Other outstanding elements included to guarantee the efficiency of the membranes area: a vibration system, a degassing device a double collector of permeate. All these features guarantees a high quality effluent disinfected and ready for water reuse.