What is a Membrane Bioreactor (MBR)?

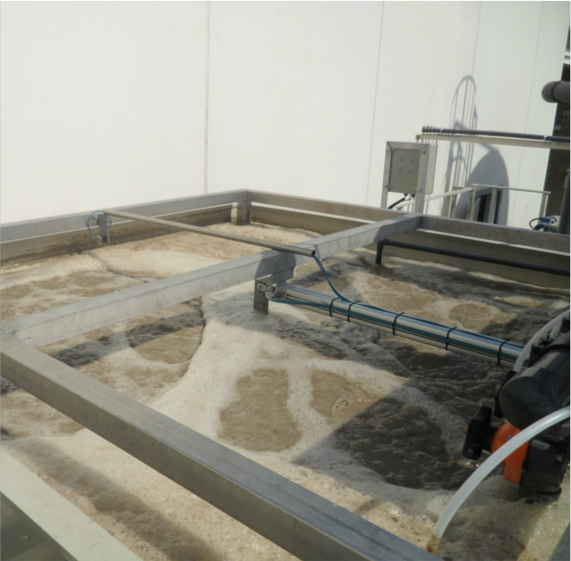

A membrane bioreactor (MBR) is a wastewater treatment process that combines membrane filtration with biological treatment. A suction force is applied to draw the water through the membrane, while the sludge is retained on the membrane surface

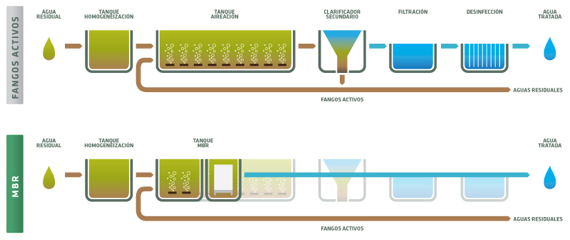

MBR is a proven technology that offers important advantages over the conventionally activated sludge process. MBR retains the biomass completely thus the biological reactor can work at high biomass concentrations, as a result a higher effluent quality is achieved.

When ↑ MLSS ⇒ ↓ Volume

When ↑ MLSS ⇒ ↓ Cm

When ↑ MLSS, Cm ct and V cte. ⇒ Increase in degradation capacity

Better effluent quality

Smaller space requirements

Ease of automation

Lower sludge production

MBR Configuration

The membrane units can be installed either directly in the reactor or in downstream filtration tanks. Both ways ensure that activated sludge, bacteria and viruses are safely retained there. A conventional secondary settling tank is no longer needed to achieve the highest effluent quality.

MBR Internal Configuration:

Biológical Reactor + UF Membranes

MBR External Configuration:

Biológical Reactor + UF Membranes

Advantages of MBR Technology

Due to…

- No need for gravity settling step,

- Total retention of colloidal biomass,

- Retention of both biodegradable and non biodegradable SS

- High biomass concentrations in the reactor

- Operation with longer cellular retention time

We achieve…

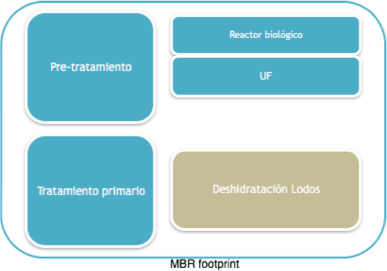

- Smaller plant footprint

- Specialization of bacteria to degrade slowly biodegradable matter (emerging contaminants, pesticides,…).

- High efficiency in the elimination of nitrogen

- Increase in the treatment capacity of an existing reactor

- Lower sludge production

- Wastewater disinfected (regarding bacteria and considering a 0,02 microns porous size)

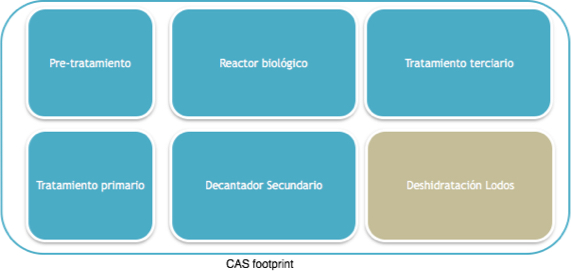

MBR vs CAS

CAS

Footprint: X m2

Organic Load: X KgCOD/day

Mlss: 2000 mg/L

Sludge production: X Kg

MBR

Footprint: ¼ X m2

Organic Load: 2·X kgCOD/day

Mlss: 8000 mg/L

Sludge production: ½ X kg